ABS Plastic Car Model Parts are crafted from high-quality ABS plastic, offering excellent toughness, impact resistance, and durability. These parts are specifically designed for use in car models, ensuring they meet stringent standards for strength and performance. The advanced material properties make them ideal for both aesthetic and functional components.

OEM/ODM Competitive Factory Price ABS Plastic car model Parts Plastic Injection Molding Parts

ABS Plastic Car Model Parts are produced using precision injection molding technology, delivering high accuracy, smooth finishes, and consistent quality. Customization options are available for dimensions, colors, and surface treatments, such as painting, plating, silk-screen printing, or hot stamping, to meet diverse client requirements.

|

Name

|

ABS plastic car model

|

|

Product Description:

|

OEM&ODM plastic injection molding Molds & Parts

|

|

Plastic Materials:

|

PS, ABS, PP, PVC, PMMA,PC, POM, PA66, PA6, PC/ABS, HDPE, TPU, PET,etc.

|

|

Dimension

|

Max. part length up to 2 meters

|

|

Standard:

|

ISO9001, ISO14001, IATF16949, CCC

|

|

Other materials:

|

Rubber, Slilconce rubber

|

|

Quality:

|

RoSH and SGS standard

|

|

Feature:

|

No marking, no flash

|

|

Size:

|

According to your 2D, 3D Drawing

|

|

Color, shape, size:

|

Customized

|

|

Surface treatment

|

Polish,painting,vacuum plating,printing

|

|

Processing procedure

|

Tooling---> injection molding--->primer painting spraying--->plating--->top coating--->printing--->finished product

|

|

QC check point

|

Dimension, outlook( color, surface finish etc.), adhesion, alcohol tolerance, and other quality check points as customer's requirements or product's applications.

|

|

Package:

|

Standard exported Wooden box packed, Plastic film,plastic tray etc. As clients’ requirements

|

|

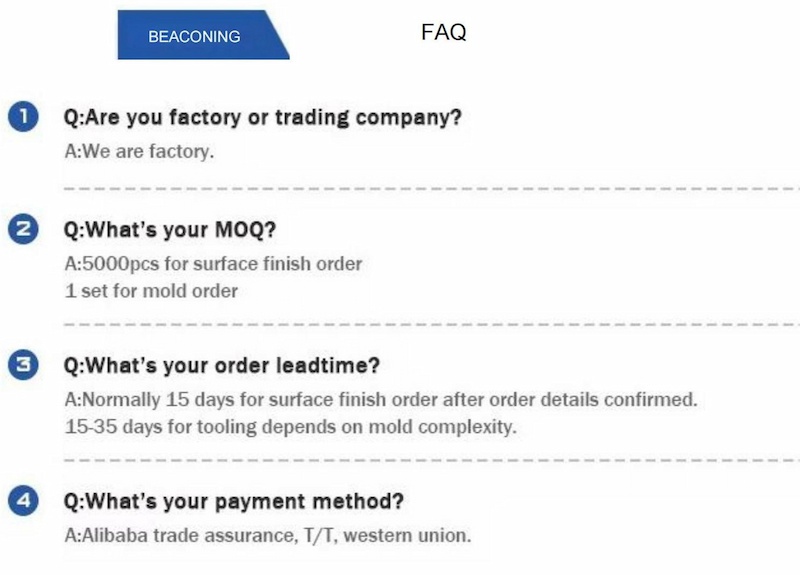

Lead Time:

|

Normally mold tooling takes 15-30 days, 10-30 days for mass production depends on order quantity.

|

|

Export Country:

|

Europe, America, UK, Canada,Germany, Italy,etc.

|

|

Experience:

|

10 years experience in plastic injection mold making and plastic prouducts produce.

|

|

Mould Base:

|

Hasco Standard, European Standard, World Standard

|

|

Mould Base Material:

|

LKM, FUTA, HASCO, DME,...etc. Or as per Customer's Requirement.

|

|

Surface Finish:

|

Texture(MT standard), Gloss polishing

|

|

Cavity/Core Steel:

|

S136, P20, 718, 8407, NAK80, H13 etc.

|

|

Mould Life:

|

100,000 to 500000 Shots. (According to your working environment.)

|

|

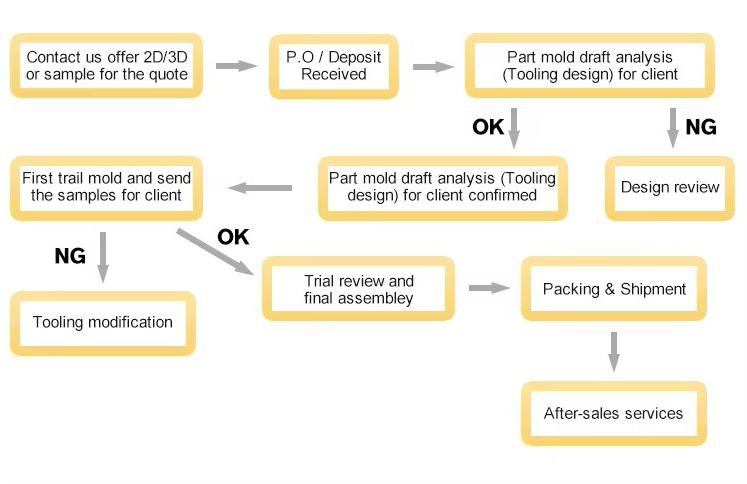

Order processing procedures:

|

1. Confirm drawing, order qty, surface treatment, packing, shipping and price.

2. Make pre-production samples.

3. Mass production.

4.Customer inspection or self-inspection as customer's requirements. 5. Arrange shipment. We can provide shipping assistants, customers can also arrange shipments themselves.

|

Dear Customers,

Please note that we only provide customize service, we ont sell the plastic parts displayed on our website.

We make plastic injection mold and plastic parts according to the 3d drawing provided by dear customers.

Thanks for your understanding,we appreciate your trust in us!

Looking forward to working with you!

HOW TO ORDER

Tags :

20-year brand,

Worthy of trust

Contact us today for a quote or for more information

Let’s Talk